Understanding Impact Driver Bits

Before diving into the specific brands, let’s understand the importance of impact driver bits. Impact driver bits are the attachments that connect to the chuck of an impact driver and transfer the rotational force to the screw or bolt. They are designed to withstand the tool’s high torque and impact forces, ensuring efficient and reliable fastening.

Irwin: The Best Impact Driver Bits for Versatility and Durability

Impact drivers have become an essential tool for many professionals and DIY enthusiasts due to their power and efficiency in driving screws and bolts. However, the effectiveness of an impact driver largely depends on the quality of the impact driver bits used. In this article, we will explore some of the market’s a top impact driver bit brands, specifically focusing on Irwin impact driver bits.

Irwin Impact Driver Bits

Irwin Tools is a renowned tool industry brand known for its high-quality and durable products. Irwin impact driver bits are no exception. These bits are specifically engineered to withstand the extreme forces generated by impact drivers, ensuring optimal performance and longevity.

One of the critical advantages of Irwin impact driver bits is their versatility. They are compatible with various impact driver models and can be used for various applications. Whether you’re working on woodworking projects, metal fabrication, or general construction, Irwin impact driver bits are designed to deliver consistent results.

Irwin offers a diverse range of impact driver bit sets, catering to different needs and preferences. Their bits are made from high-quality materials such as industrial-grade steel, enhancing their durability and wear resistance. The precision-machined tips provide a secure fit and reduce cam-out risk, improving overall fastening efficiency.

Wiha Impact Driver Bits

Another notable brand in the impact driver bit market is Wiha. Wiha impact driver bits are known for their exceptional quality and precision engineering. These bits are crafted to focus on durability and performance, ensuring reliable fastening even in demanding applications.

Wiha impact driver bits are made from high-grade tool steel, offering excellent hardness and wear resistance. The bits are hardened to enhance their durability, allowing them to withstand repeated high torque and impact forces. The precision-machined tips ensure a precise fit, minimizing the risk of stripping screws or bolts.

Makita Gold Impact Driver Bits

Makita is a well-established brand in the power tool industry, and its impact driver bits live up to the company’s reputation for quality and innovation. Makita Gold impact driver bits are engineered to deliver superior performance and longevity, making them popular among professionals and DIYers.

These bits feature a torsion zone design that absorbs the high torque generated by impact drivers, reducing the risk of breakage and extending their lifespan. The precision-fit tips provide optimal contact with screws and bolts, allowing for efficient power transfer. Makita Gold impact driver bits are also designed to reduce wobbling during fastening, resulting in more accurate and secure connections.

Milwaukee Shockwave Impact Driver Bits

Milwaukee is a trusted name in the power tool industry, and their Shockwave impact driver bits are highly regarded for their durability and versatility. These bits are specifically engineered for use with impact drivers and are designed to withstand the harshest job site conditions.

Milwaukee Shockwave impact driver bits feature a proprietary heat treatment process that enhances their hardness and durability. This treatment also allows the bits to absorb the high torque and impact forces without sacrificing performance. The optimized shock zone geometry reduces stress at the tip, minimizing the risk of tip breakage and extending the overall lifespan of the bits.

DeWalt Impact Driver Bits

DeWalt is a well-known brand that offers a wide range of power tools and accessories. DeWalt impact driver bits are designed to provide exceptional performance and durability, meeting the demands of professional tradespeople and DIY enthusiasts alike.

These bits are engineered with a hardened core that increases their strength and resistance to wear—the optimized torsion zone flexes under load, absorbing the torque and reducing the risk of breakage. DeWalt impact driver bits also feature a precision-machined tip for a secure fit and improved fastening accuracy.

Bosch Impact Driver Bits

Bosch is a globally recognized brand known for its high-quality power tools and accessories. Bosch impact driver bits are designed to deliver reliable and efficient performance, making them a popular choice among professionals.

These bits are constructed from high-grade steel, ensuring durability and longevity. Bosch impact driver bits feature an Xtended Torsion Zone that absorbs torque and reduces the risk of breakage. The precision-engineered tips provide a secure fit, preventing cam-out and improving fastening efficiency.

Factors to Consider When Choosing Impact Driver Bits

When selecting impact driver bits, there are several factors to consider to ensure you make the right choice for your needs:

- Material: Look for impact driver bits made from high-quality steel or alloys that offer durability and resistance to wear.

- Compatibility: Ensure the bits are compatible with your impact driver model.

- Variety: Consider the range of sizes and types of bits included in the set to meet your specific requirements.

- Durability: Check for features like hardened cores, torsion zones, and optimized geometries that enhance the bit’s durability.

- Precision: Look for bits with precision-machined tips that provide a secure fit and reduce the risk of stripping screws or bolts.

Comparison of Impact Driver Bit Sets

Here is a brief comparison of the different impact driver bit sets:

| Brand | Material | Versatility | Durability | Compatibility |

|---|---|---|---|---|

| Irwin | Industrial-grade steel | High | High | Compatible with various impact drivers |

| Wiha | High-grade tool steel | High | High | Compatible with various impact drivers |

| Makita Gold | Steel with torsion zone design | High | High | Compatible with various impact drivers |

| Milwaukee Shockwave | Proprietary heat-treated steel | High | High | Compatible with various impact drivers |

| DeWalt | Hardened steel | High | High | Compatible with various impact drivers |

| Bosch | High-grade steel | High | High | Compatible with various impact drivers |

Tips for Using Impact Driver Bits Effectively

To make the most out of your impact driver bits and ensure optimal performance, consider the following tips:

- Use the right bit for the job: Select the appropriate bit based on the type of screw or bolt you’re working with.

- Securely attach the bit: Ensure the bit is correctly secured in the impact driver’s chuck to prevent slippage or wobbling.

- Apply consistent pressure: Maintain a steady and even pressure while driving screws to prevent damage to the bit or fastener.

- Avoid over-tightening: Impact drivers generate significant torque, so be cautious not to overtighten screws, as it may lead to stripping or damage.

- Use the correct speed and power settings: Adjust the speed and power settings on your impact driver to match the requirements of the task at hand.

- Replace worn or damaged bits: Regularly inspect your impact driver bits for signs of wear or damage and replace them as necessary to ensure safe and efficient operation.

Test Results

Having a lovely impact driver is a very nice thing to tackle that big project, but you need an impact bit that goes along with it. Otherwise, you’re just going to cause much damage. So, the question is, which one of these brands is the best? Today, we’ll test 10 different brands, one claiming to be 50 times better than the competition. So, let’s get the testing underway and see which one of these brands is the best.

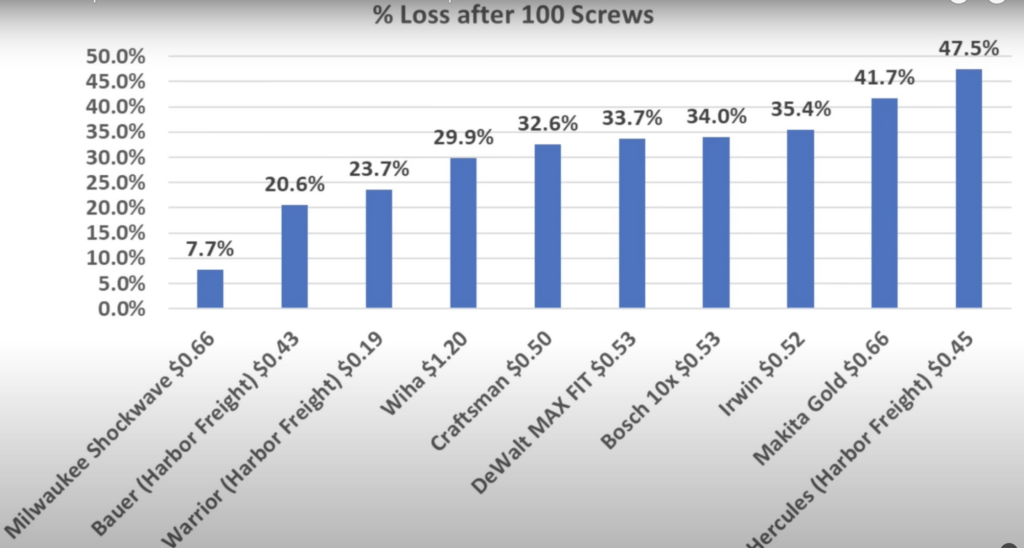

In the first test, we’ll drive 100 screws for each brand of impact bit and then compare the amount of wear under a microscope. We’ll measure the twisting force required for the driver bits to cam out when they are new. Then we’ll measure how much twisting force is required to cause the bits to cam out after driving a hundred screws. Finally, we’ll measure the twisting force required to break each driver bit.

Driving drywall screws into 4×4 puts a tremendous load on the screws and the impact bit. To standardize the testing as much as possible, I drove all 1000 screws into the pressure-treated 4x4s approximately one-quarter inch before testing the impact bits. All the 4x4s were purchased the same day from the same stack of lumber and were maintained in a dry environment for a couple of weeks before the testing.

Costing only $5.99, the least expensive brand we’ll be testing is this Warrior brand 32-piece set that’s only 19 cents per piece. They’re constructed of chrome vanadium and made in China. Some say that impact-rated bits don’t last as long as these, which are not impact-rated, so it will be exciting to see how the Warrior brand compares.

Quite a bit of wobble with the Harbor Freight Warrior. Harbor Freight Warrior, not designed for use with an impact driver, survived all 100 screws. I see more than twice as much wobble as the Harbor Freight Warrior. At 43 cents each, these Bauer brand impact-rated bits.

They are constructed with precision tolerance heavy-duty hardened S2 tool steel with a shock-absorbent zone for heavy-duty use. They claim their precision design reduces stripping and resists corrosion. They are made in Taiwan. Compared to the Warrior, the Bauer offers a much better fit with a tiny wobble.

The excellent tight fit of the Bauer made driving the screws very easy. This Hercules brand is also sold at Harbor Freight, costing 45 cents each, only 2 cents per unit more than the Bauer brand. Hercules impact-rated insert bits use exclusive bit fit technology to provide exceptional fit and reduce stripping. They’re built with hardened S2 tool steel. These impact bits are professionally made in Taiwan. Unfortunately, the Hercules doesn’t offer a perfect fit—quite a bit of wobble. I could tell that the Hercules had quite a bit of wobble compared to the Bauer.

Costing 50 cents per unit, is this Craftsman brand? It claims to deliver improved performance through its optimized torsion zone. It is constructed of S2 shock-resistant tool steel for maximum durability. Its CNC machined bit tip ensures precise fit and screw heads, reducing cam out opportunities. It is made in Vietnam. The Craftsman offers a much tighter fit than the previous three brands. The Craftsman didn’t seem to grip the screw as well as the Bauer.

Costing 52 cents each is this Irwin brand, which claims its forged bit delivers superior fitment, which reduces stripping and increases life by three times. Manufactured with heavy-duty cold-forged high-grade steel to withstand high torque output and is made in China.

Everyone has a good fit, but there’s some wobble. I could tell the Irwin had more wobble than some other brands, costing just 53 cents or one cent more than the Irwin. Is this Bosch brand, which claims to deliver ten times the life over standard impact bits? An extended torsion zone helps to absorb the high torque of new impact drivers.

Precision-engineered tips for a tighter fit and less cam out. Heat-treated manufacturing for a more vital bit. It is made in Vietnam.

The Bosch offers a very tight fit, very similar to the Craftsman. The bar started great, but the performance degraded quite a bit by the end of the test. Costing 53 cents each, the same as the Bosch brand, is this DeWalt Max Fit, which claims its optimized tip geometry reduces wear and creates an ideal fit with every fastener?

CNC manufacturing ensures that the product consistently delivers the highest level of quality. Each bit features a unique torsion zone to deliver long life in metal and wood fastening applications. It is made in China.

Very nice tight fit with a DeWalt, with a tiny wobble. I like the performance of the DeWalt; it provided a great fit. Costing 66 cents each, which is 13 cents more per unit than the DeWalt, is this Makita Gold designed exclusively for high torque impact drivers? Precision fit tip engineered to prevent cam out and to strip. Ten times longer life than standard insert bits. It is made in Japan.

Even though it’s a good fit with Makita, there’s more movement than compared to some of the other brands. While Makita did pretty well, it just didn’t seem to grip the screws as well as some of the other brands. Also, costing 66 cents each, the same as the Makita brand, is this Milwaukee Shockwave impact bit? A rare guard tip protects the fit over the life of the bit. It’s made of a custom alloy 76 steel, engineered to extend the bit life. Milwaukee has, by far, the most ambitious claim, saying that their product lasts up to 50 times longer than other impact bits.

Very nice fit by Milwaukee, with a tiny wobble. It is professionally made in China. I was impressed with the Milwaukee; it seemed as good as new throughout the test. Passing at $1.20 each, or very close to twice as much as the second most expensive brand, is the Wiha brand. It claims to offer 30 times performance over standard bits.

It claims to have a unique energy-absorbing dual-material design. Precision heat-treated and premium chrome vanadium tool steel. Manufactured by Wiha Vietnam and engineered by Wiha Germany.

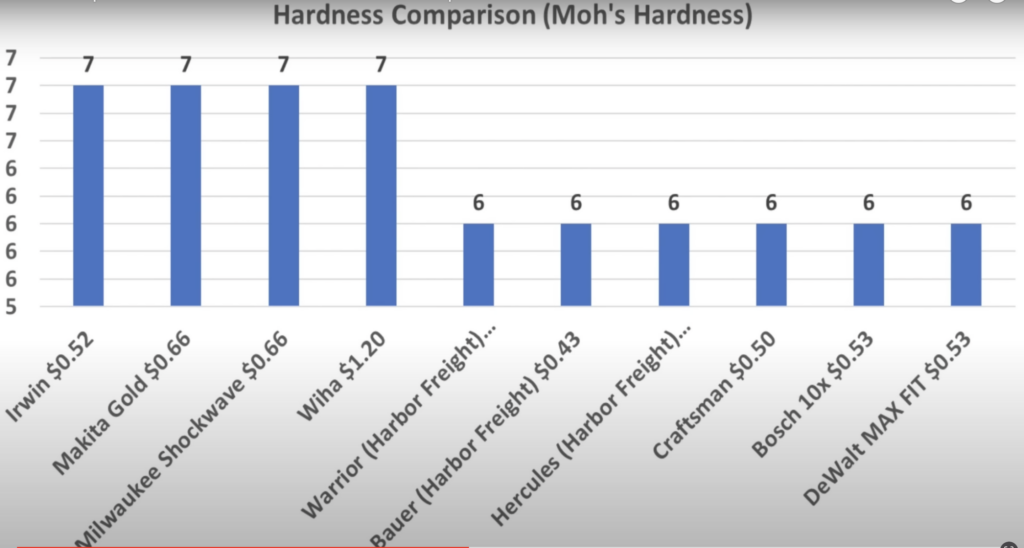

Hardness Comparison (Moh’s Hardness)

The Wiha has a little more wobble compared to some other brands. The Wiha didn’t have a perfect fit but did a terrific job and seemed to be in great shape by the end of the test. Most hardness tests are not the gold standard for determining metal hardness, but they’ll provide us with some great information on whether the tip hardness impacts durability.

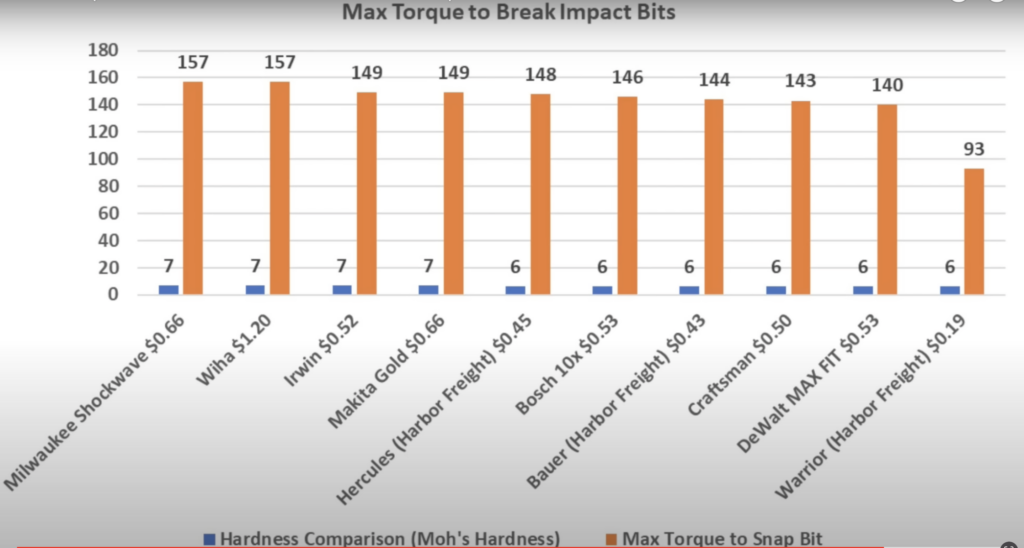

The Irwin, Makita, Milwaukee, and Wiha all seem around a 7 in hardness, compared to a 6 for the other brands. It’ll be interesting to see if the more complicated bits show less wear and more strength.

Let’s look at all the driver bits to see how much wear took place. The new Harbor Freight Warrior is on the left, and the one used for 100 screws is on the right. The part of the driver bit that experiences direct impact shows quite a bit of wear, and some of the metal along the edge of the bit is elevated.

The Bauer did very well and is in much better condition than the Warrior brand by showing very little wear along the leading edge of the flutes. The same manufacturer likely makes the Hercules as the Bauer, but the bit just didn’t fit the screw as well as the Bauer.

As a result, there’s quite a bit more wear. While the Craftsman provided a reasonably tight fit, the width of the flutes near the tip is much narrower, and the tip seems slightly twisted. While there’s some wear on Irwin’s leading edge of the flutes, it appears less worn than the Craftsman.

The Bosch was the lightest of all the brands, and it appears to have quite a bit of damage to the flutes. While there’s visible wear to the leading edge of the flutes of the DeWalt, it has less wear than the Bosch. While there is some rounding on the leading edge of the flutes of the Makita, it seems to have less wear than some of the other brands.

The Milwaukee has held up very well, with minimal wear along the flutes’ leading edge. The Wiha could have done better than the Milwaukee.

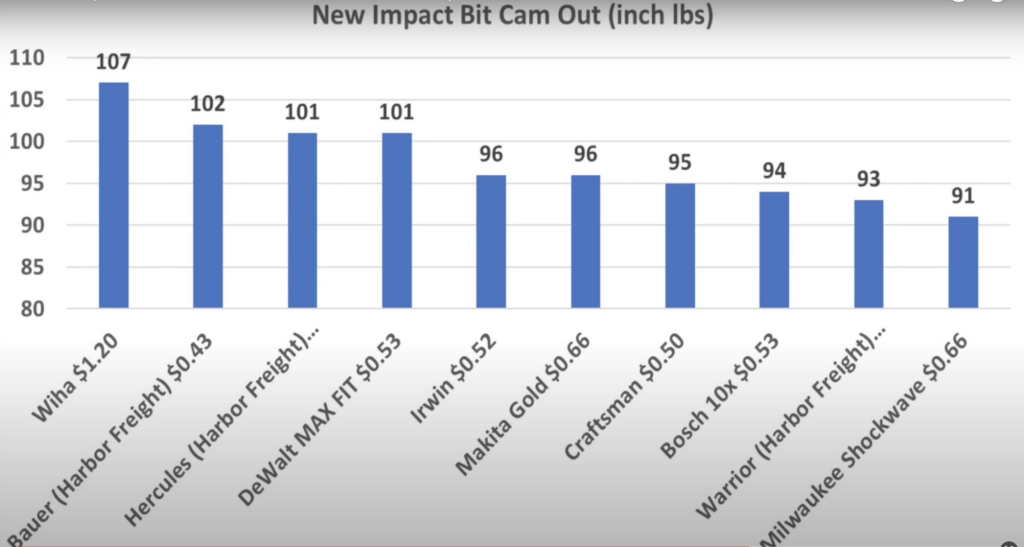

In the next test, we’ll measure the cam out the strength of the new and the used driver bits. Several things affect cam out, including the bit geometry, hardness of the metal, and the type of coating used on the bit. We’ll use a drill press to apply a downward force on the torque adapter and the impact driver bit.

The belt on the drill press has been removed to avoid interfering with test accuracy. I placed a weight on the lever arms of the drill press and attached a 5-pound weight on a rope. The downward force applied to the impact driver is 27.2 pounds.

I drilled a pilot hole in cured Osage Orange, a Hedge Apple. I removed and installed a new screw between each test. I had to switch brands of screws since the original drywall screws, along with several other brands, were too brittle and broke with 27.2 pounds of downward force on the impact driver bit. Instead of camming out, the new Harbor Freight Warriors snapped at 93-inch pounds, exposing the weakness of using an impact driver bit not designed for high torque.

After installing a new screw, the Harbor Freight impact driver bit used to install 100 screws was tested and did well, camming out at 71-inch pounds.

The new Bauer did very well, coming out at 102-inch pounds. The used Bauer did better than the Warrior, camming at 81-inch pounds. Very impressive. The new Hercules did very well at 101 pounds, just one pound less than the Bauer. The used Hercules, which had much more visible wear than the Bauer, came down at only 53-inch pounds.

The new Craftsman did pretty well at 95-inch pounds. The used Craftsman did better than the Hercules but not as well as the Bauer at 64.

- The new Irwin lost grip at 96-inch pounds. The used Irwin was very close to the Craftsman at 62.

- The new Bosch slipped out of position at 94. The used driver bit did the same as the Irwin at 62.

- The new DeWalt lost traction at 101-inch pounds. The used DeWalt did much better than average at 67-inch pounds.

- The new Makita camped out at 96. The used Makita struggled at 56.

- The new Milwaukee lost traction at 91. The used Milwaukee did the best yet at 84, which is nearly as good as the new impact driver bit.

- The new Wiha did the best yet at 107-inch pounds. The used Wiha did well above average at 75 but less than the Milwaukee.

These screws we use, and as you can see, they held up very well.

New Impact Bit Cam Out (inch lbs)

The Wiha did a tremendous job at avoiding cam out, but the Bauer, Hercules, and DeWalt were close behind. All the bits survived this test except for the Harbor Freight Warrior. In fairness, the Harbor Freight Warrior is not designed for extreme torque loads, exposing the weakness of using this bit style.

Used Impact Bit Cam Out (inch lbs)

Even though Milwaukee cammed out sooner than a lot of the competing brands, it came out on top in the competition after a hundred screws. Harbor Freight Bauer brand did well, finishing second, and the Wiha third. Even though the Warrior held up very well after 100 screws, they’re incredibly brittle.

% Loss After 100 Screws

The last test provides excellent information on how the driver bits handle low to medium torque loads. Still, the next test will provide great information on the most vital driver bit for high torque applications. I used self-tapping steel screws and 200 pounds of downward force for this next test to prevent the driver bits from camming out before snapping. We won’t test the Harbor Freight Warrior again since it snapped at 93-inch pounds in the previous test.

The Bauer showed impressive strength, snapping at 144-inch pounds. The Hercules did slightly better at 148-inch pounds. The Craftsman was less intense than the Bauer or the Hercules at 143-inch pounds. The Irwin did the best yet at 149-inch pounds, which is very impressive. The Bosch didn’t do as well as the Irwin at 146-inch pounds.

The DeWalt snapped at 140-inch pounds, the lowest of all the driver bits except for the Harbor Freight Warrior. Compared to the other brands, the Makita flexes, and twists the most before breaking. You’ll see the Makita begins to cam out before snapping. It still did great at 149-inch pounds. The Milwaukee claimed to last 50 times longer than the competition and did the best yet at 157-inch pounds, which is very impressive. The Wiha tied the Milwaukee at 157-inch pounds, again very impressive.

Max Torque to Break Impact Bits

If money is not a factor and it’s all about high torque capability, the Milwaukee and the Wiha showed the most Braun at 157-inch pounds. However, Irwin and Makita were very close behind at 149. According to the Mohs hardness test, the most vital 4 bits were also made of the most brutal metal.

However, other brands, like the Hercules, were just a little behind. The brand makes a massive difference in impact driver longevity. However, I quickly destroyed some delicious quality bits because of being in a hurry and because of some bad habits. One of the quickest ways to destroy a bit is by not applying enough downward force. Even if the driver bit doesn’t cam out, excessive movement causes much friction from the movement, wearing out the flutes.

Another bad habit I’ve had is to remove the driver bit while the impact driver is still in motion. This creates much wear on the leading edge of the flutes, especially toward the tip of the impact driver. Improving these two things has made a massive difference in the lifespan of the bits.

Conclusion

So, which impact driver bit brand do you think is the best based on your experience?

I’ve never used the Milwaukee brand before, but I’m impressed. It claims to be up to 50 times longer lasting than the competition. I’m not sure it’s that good, but I know I removed all 1,000 screws with almost all 1,000. Three of the screws broke in the process, and it’s a perfect brand, the best of all the ones we’ve tested.

Bauer did a very respectable job, so if it’s all about the price, Bauer might be an impact bit you might consider. All my test ideas, including this one, come from viewers. So, if you have a test idea, I hope you’ll take the time to leave a comment. I read and reply to as many comments as possible. Thanks so much for reading the test. Please take care and look forward to next time.

Choosing the right impact driver bits is crucial for achieving efficient and reliable fastening results. Irwin, Wiha, Makita Gold, Milwaukee Shockwave, DeWalt, and Bosch are all reputable brands offering impact driver bits that cater to various needs and budgets. Consider material, durability, compatibility, and versatility when selecting the best impact driver bit set for your projects. With the right bits in hand, you can maximize the performance of your impact driver and tackle a wide range of applications with confidence.

FAQs

Q: Can I use impact driver bits with a regular drill?

A: Impact driver bits are specifically designed for impact drivers and may not perform optimally with regular drills. It’s recommended to use bits designed explicitly for regular drills.

Q: How long do impact driver bits last?

A: The lifespan of impact driver bits depends on factors such as usage frequency, material quality, and the type of applications they are used for. With proper use and maintenance, quality impact driver bits can last considerably.

Q: Can I use impact driver bits with a cordless drill?

A: In most cases, impact driver bits are compatible with cordless drills. However, impact drivers are specifically engineered to deliver high torque and impact forces, which cordless drills may not fully utilize.

Q: Can impact driver bits be used with manual screwdrivers? A: Impact driver bits are not designed for use with manual screwdrivers. Impact drivers typically generate the rotational force required for impact driver bits, and using them with manual screwdrivers may not yield satisfactory results.

Q: Are impact driver bits interchangeable between different brands?

A: Impact driver bits are generally interchangeable between different brands as long as they have the same size and compatible shank design. However, it’s always recommended to check the compatibility of the specific bits with your impact driver model.

Leave a Reply