In the US submarine fleet, an adhesive cloth tape is called “EB Green,” as the duct tape used by Electric Boat was green. It is also called “duck tape,” “riggers’ tape,” “hurricane tape,” or “100-mph tape,”; a name that comes from the use of a specific variety of duct tape that was supposed to withstand up to 100 mph (160 km/h; 87 kn) winds. The tape is so named because it was used during the Vietnam War to repair or balance helicopter rotor blades.

So when I was growing up, one of my favorite TV series was called MacGyver. MacGyver was a former Special Forces operator who seemed to solve just about any problem he encountered with duct tape or all-purpose tape. Occasionally, he’d throw in a little bubble gum or baling wire, but the number one tool of choice was always duct tape.

Many of you have asked me to test duct tape to see if a name brand is better than the rest. What’s interesting about this is that we’ve tested Threadlocker and some epoxies in the past. We’ve discovered some of the lesser-known name brands came out on top, so today, will it be an underdog that comes out on top regarding the strength and the quality of these various types of all-purpose tapes?

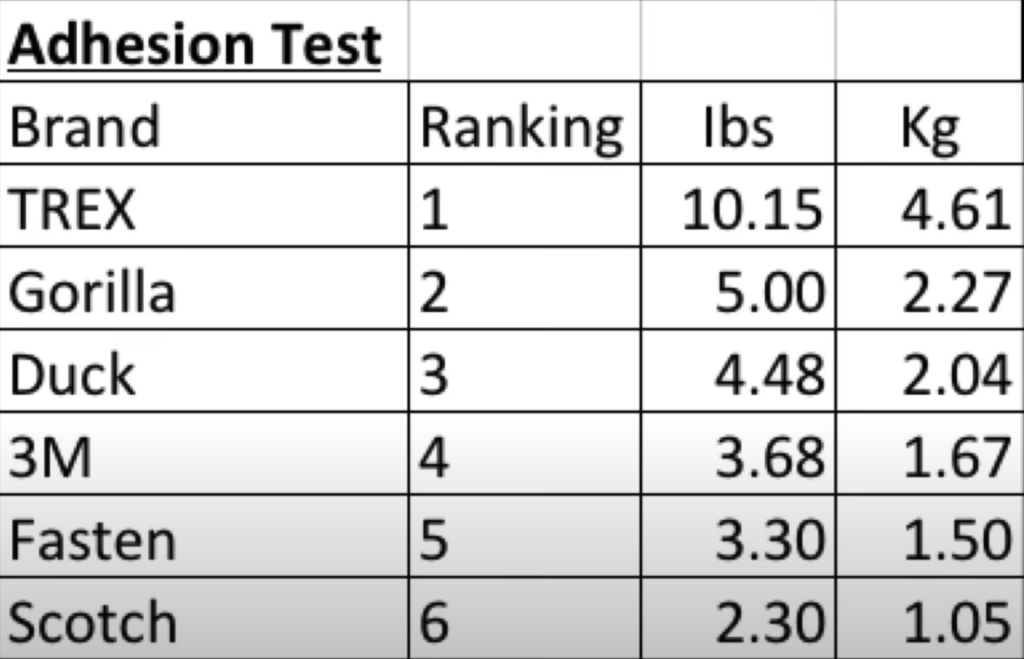

Anyway, let’s go and get this project underway and find out which one, if any, is the best. The first test we’ll be doing today is [to] determine how well these tapes will stick to a surface. The surface I’ve chosen is an artificial laminate. This is an old table. But this surface is perfect regarding different adhesive products sticking to it. So, this makes good sense. Also, the temperature in the room is between 70 and 75 degrees today. I have heat in the shop, so that’s one factor that makes a big difference in how well a tape will stick.

So, to make this a fair test, I want to ensure that each tape has a fair chance to stick to the surface. To do that, I need to apply equal force on each tape. So, I’m going to use this appliance dolly, these wheels. I cut this up for this test, but I will flip this over and apply 25 pounds of downward force directly on top of this set of wheels. Now, I will roll this across the tape several times to ensure that every tape has the same amount of downward force applied to it.

So, to measure how well these tapes stick, I’ve decided to take this container, add a funnel, and gradually fill it with water until the tape lets go. Then we’ll weigh how much this container weighs to see how well these products stack against each other. I added 4.7 ounces; that’s when it started giving. So, Gorilla Tape weighed over 5 pounds before it started to slide.

Okay, so the T-Rex held just in wrenches alone over five pounds. I’m holding a couple of clamps in my hand because the max on this scale is five pounds, so I get an error message when I go over, so that’s over five pounds. I’ll weigh these in a minute. So that’s four pounds 15.6 ounces. We get another 3 or 3.2 ounces when adding these two clamps. And right at 5 pounds of water, all totaled, T-Rex held over 10 pounds.

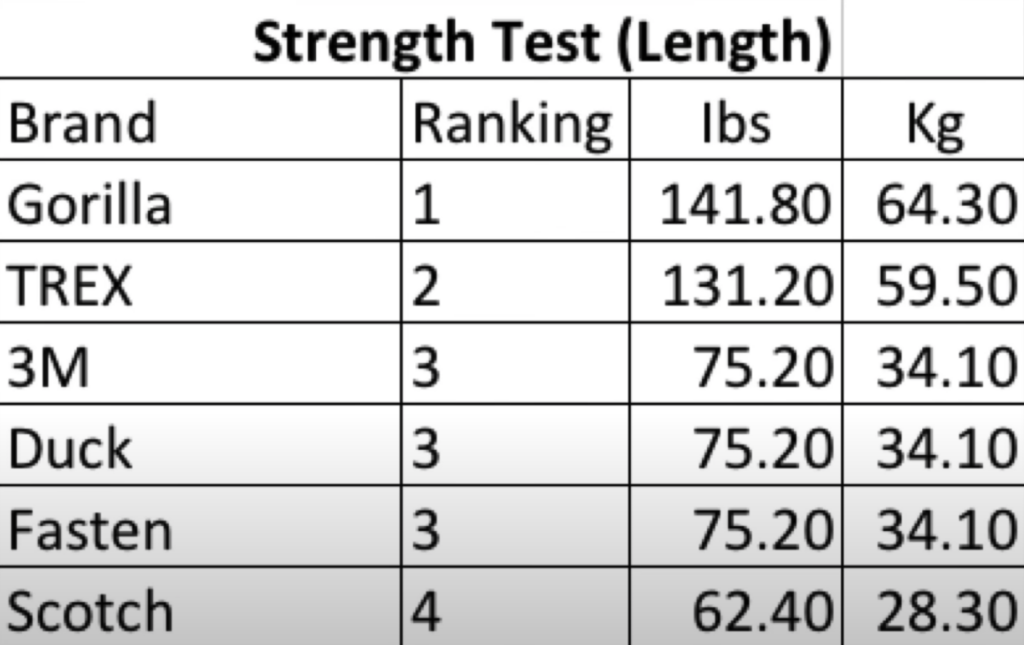

Next, we will measure the tensile strength of each of these tapes. This device that I put together includes two pipes and a hinge. This moves freely so that I will apply a solid layer of tape all around both pipes and then we will apply weight on the first red line, which is six inches out from the pivot point. And we will keep applying weight until the tape breaks, giving us a reasonably accurate tensile strength measurement.

So we want to know how much downward force this system will apply. So what I’ll do is measure how much downward force takes place. As you can see, it already weights it just from the bar’s weight, and quite a bit of force is being applied here. And so, I will take the 25-pound plate, measure the amount of downward force right at the base, and then each of these pieces of tape out to the end to see how much total force we get.

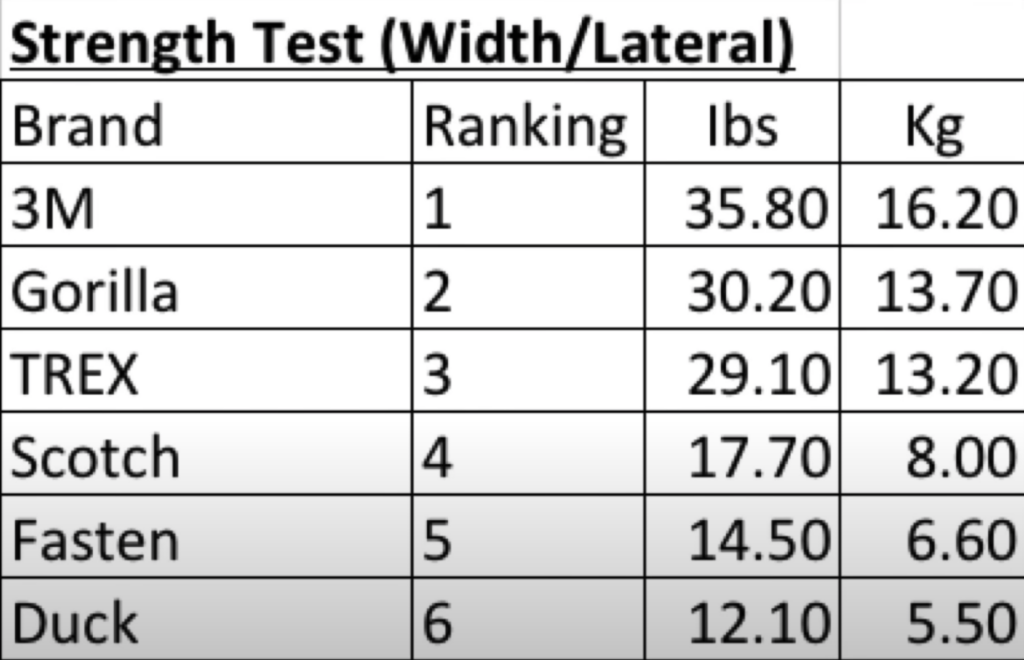

So far in our testing, we’ve measured the ability of these all-purpose tapes to stick and how much strength they have lengthwise. Now we’re going to measure the strength widthwise. So I’m going to use this little gadget that I’ve put together to apply this tape, and then I’m going to apply a downward force, and we’re going to measure how much force it takes to rip the tape at this gap.

Adhesion Test

I learned a lot from this test. I had yet to learn that the brand made a big difference. What we saw here, though, was varying levels of elasticity, tackiness, and strength with each of these brands.

Strength Test (Length)

Many of you guys have asked me to provide my opinion on these different products, and I don’t want to do that. I want you guys to decide which products you would buy. Um, one of the reasons for that is that I’m not trying to influence a purchase.

Strength Test (Width/Lateral)

Any of these companies does not sponsor me, so if you choose to buy these products, that’s fine. It doesn’t help me financially if you choose not to. Again, it doesn’t hurt me financially. What I’m trying to do is, though, provide you with information to help you make a brand choice or make a purchase choice.

Another thing that I’m interested in doing with these tests, though, is to put a little pressure on the underperforming brands to improve the quality of their products. To me, many consumers go in, and they buy a product, and because they don’t have the time or the resources to compare qualities, they continue to stick with a particular brand even though it may be a terrible product. Such tests like this expose the weakness of these products and force manufacturers either to improve their game or to lose market share.

Anyway, thank you so much for reading this test. I hope you’ll like, share, and subscribe. Please take care, and I look forward to seeing you next time.

Leave a Reply